Practical engineering philosophy

Industrial foundations, walls and roof. The “roof” was all they wanted but…

Client was in danger of building a warehouse with foundations holding 16kNm where 360kNm is required.

Reinforced concrete… Factory floor with custom foundations.

A huge disaster prevented. Floor redesigned, bridges, anchors … holding 200t loads, 2MNm bending, on soft wet soil.

Rail road, heavy industry - Australia.

Client protected from getting their products shipped back.

EU Railroad spring / damper system.

Client protected from bad investment. Bad solution removed, correct solution found.

Concrete truck attachment.

Recovery from a failed DIY attempt. 3 month project rescued in 3 weeks. In the end - verified and certified for Swedish market.

Repeated / late requests for clarification from reviewers addressed.

Rear Under Protection (RUPD) - car crash sim.

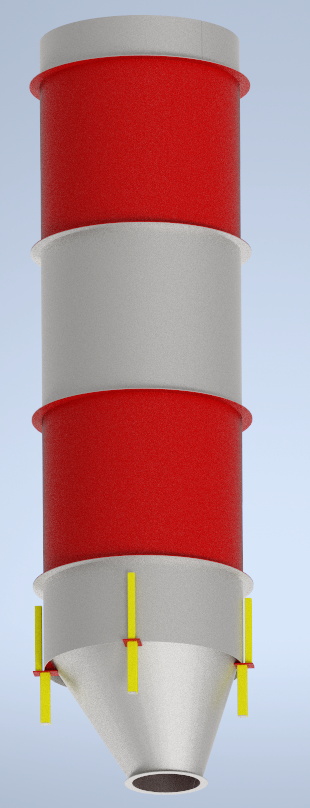

Sand holding silo, for a cement factory. From design - to manufacturing drawings… in weeks.

20t lifting winch frame for offshore crane.

Product line expanded towards a 2x stronger solution.

2tonnes heavy, 5m tall CNC machine.

A real patent... :)

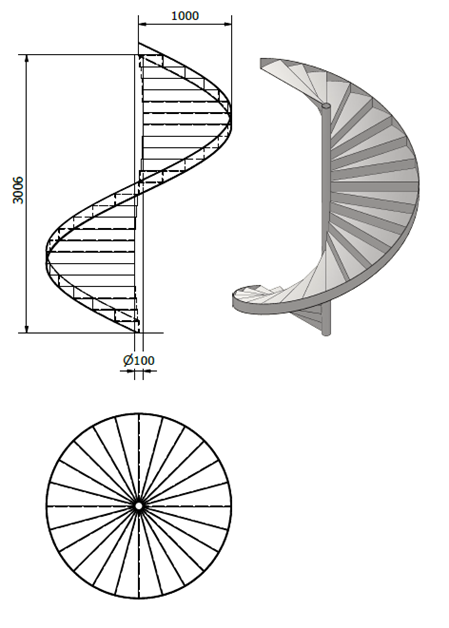

Preliminary design.

A "research grade" task... experimental reinforcement.

Calibrated for crack propagation.

Overkill, but... dynamic load safe.

500 ULS cycles... EN3 compatible.

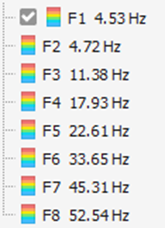

1. Fatigue safe 2. Feels stable (not "shaky"). 3. Certifiable for CE mark.

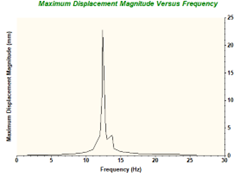

Natural frequency - below 10Hz is not good.

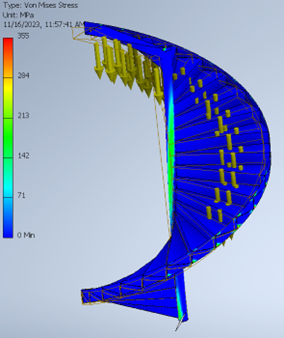

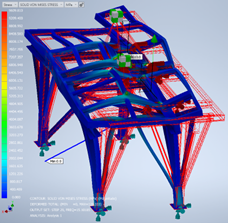

Stress in ULS case... ok

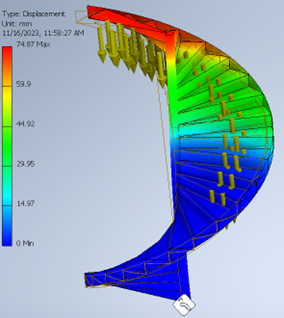

Displacements...

Manufacturing / production drawings generated...

Frame dynamic response - for shaky engines, and moving parts.

The frequency response is scary bad.

After adjusting, one frequency remains dominant, and is plausible to dampen effectively.

Thermal analysis

Thermal analysis is a BEAST…

Coupled with stress fields, fatigue, gets even harder.

Managing of tasks can benefit from “fast engineering feedback”. It often helps:

Reality is perfect, it never makes an error.

It was not made for us, it knows not we exist.

Observe the unpredicted, predict the unobserved.

Inductive and deductive - converge to truth, not false (yet).

Nothing is true. Some is not false (yet).